Understanding Environmental Factors in 3D Printing

Environmental control is often overlooked but plays a vital role in 3D printing success. Factors like ambient temperature and humidity directly affect filament properties, print quality, and even the longevity of your materials. Whether you’re printing with beginner-friendly PLA or advanced engineering filaments like Nylon or Polycarbonate (PC), different materials respond uniquely to environmental conditions.

The Impact of Ambient Temperature and Humidity on Print Quality

Temperature

Ambient temperature plays a critical role in the overall success of 3D printing, as it directly influences how well a filament extrudes, adheres to the print bed, and bonds between layers. Maintaining the right temperature ensures that the material flows smoothly through the nozzle, creating consistent extrusion without clogs or interruptions.

For bed adhesion, a stable ambient temperature helps prevent issues like warping or detachment during the printing process, especially for materials like ABS or Nylon that are prone to shrinkage. Additionally, proper temperature control promotes strong layer bonding, which is essential for creating durable and high-quality prints.

Examples of ambient & enclosure temperatures for common 3D printing filaments

- PLA: 20-30°C

- PETG: 20-40°C

- ABS/ASA: 40-60°C

- PA (Nylon): 40-60°C or higher

- PC (Polycarbonate): 40-70°C

Humidity

Humidity, measured as relative humidity (RH), has a profound effect on filament performance in 3D printing. This environmental factor is often underestimated but can significantly impact print quality, material properties, and even the longevity of your filaments.

Recommended humidity levels for common filaments used in 3D printing

- PLA and ABS: Below 30% RH (up to 40% tolerable)

- PETG, TPU, Nylon: Below 20% RH

How Moisture Affects 3D Printing filaments

Moisture absorption by filaments can significantly degrade their performance during 3D printing, leading to defects and reduced part quality. Hygroscopic materials like Nylon, TPU, and PETG are especially prone to absorbing water from the air, which alters their properties.

Key points:

- Hygroscopic Behavior: Filaments like Nylon can absorb up to 10% of their weight in water within hours.

- Print Defects: Moisture causes bubbles, uneven layers, stringing, and poor interlayer adhesion.

- Mechanical Properties: Moisture alters polymer chains through hydrolysis, reducing tensile strength.

- Longevity: Prolonged exposure to high humidity can irreversibly degrade filaments.

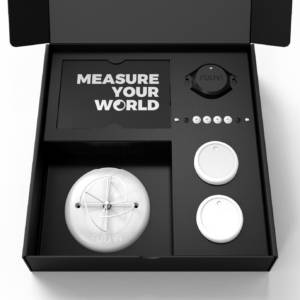

RuuviTag: Your 3D Printing Environment Assistant

RuuviTag is a versatile and highly reliable environmental sensor designed to help you monitor temperature and humidity in real-time, making it an essential tool for optimizing your 3D printing setup.

Benefits of using RuuviTag

- Track temperature ranges for specific filament types

- Monitor humidity levels to ensure sensitive filaments remain dry

- Receive alerts when conditions exceed optimal ranges

Learn more about RuuviTag and its applications

Optimizing Filament Storage with RuuviTag

Proper storage is crucial for extending the lifespan of your filaments and maintaining consistent print quality. Storing your filaments in airtight containers with desiccants or vacuum-sealed bags helps protect them from humidity.

Best practices for filament storage

- Humidity Control: Use airtight containers with desiccants, monitored by RuuviTag sensors.

- Temperature Stability: Keep storage temperatures between 20-30°C for most filaments.

- Drying Filaments: Use filament dryers set at appropriate temperatures (50-80°C) for hygroscopic materials

Diagnosing Common 3D Printing Issues with RuuviTag

RuuviTag’s precise measurements can help identify and resolve environmental causes behind common 3D printing failures.

Common issues and solutions

- Stringing and Bubbling: Use a filament dryer or improve storage conditions.

- Warping and Layer Splitting: Consider using a heated enclosure or improving insulation.

- Inconsistent Print Results: Create a log of environmental conditions for each print to identify optimal ranges.

Best Practices for Managing Your Printing Environment

- Use enclosures for temperature-sensitive materials.

- Invest in dehumidifiers or actively heated filament dryers.

- Monitor both storage and printing environments using RuuviTag sensors.

- Regularly dry sensitive filaments before use.

- Ensure proper ventilation in enclosed spaces.

3D Printing and Humidity: Frequently Asked Questions

How often should I check the humidity levels in my filament storage?

Continuous monitoring is ideal, especially for hygroscopic filaments like PLA or PETG. Weekly checks are sufficient in stable environments, but in humid areas (>50% RH), daily monitoring is recommended to prevent moisture absorption, which can degrade filament quality.

Can I still use filament that has absorbed moisture?

Yes, moisture-absorbed filament can be salvaged using a filament dryer. Drying at controlled temperatures (e.g., 45–55°C for PLA) restores printability by reducing moisture content. Studies show that drying improves mechanical properties and reduces extrusion issues like bubbling.

Are there any filaments that don’t absorb moisture?

While all filaments absorb some moisture, some filament types are less hygroscopic compared to others. PETG, for example, requires low moisture content during printing, but it has been shown to maintain its mechanical properties better in humid conditions compared to some other filaments, making it a good choice for applications requiring durability in varying environments.

How many RuuviTags do I need for my 3D printing setup?

For effective environmental monitoring, place one RuuviTag near your printer and another in your filament storage area. Larger setups may require additional sensors to account for microclimate variations across the workspace.

How humid is too humid for 3D printing?

Humidity levels above 55–60% RH are problematic for most filaments, as they lead to moisture absorption and print defects such as stringing and poor layer adhesion. Maintaining humidity between 30-50% RH ensures optimal print quality

What humidity is bad for PLA?

A: PLA performs best at humidity levels between 20–40%. Exposure to >50% RH can cause moisture absorption, resulting in weakened mechanical properties and extrusion issues like popping sounds during printing.

Is 38% humidity too dry for 3D printing?

A: No, 38% RH is within the optimal range (30–45%) for most filaments like PLA and PETG. Lower humidity (<30%) is beneficial for long-term filament storage but does not negatively impact printing performance.

What is the best humidity for 3D printing?

The ideal humidity range for most filaments is between 30–45%. This minimizes moisture absorption while avoiding issues caused by excessively dry air, such as static buildup in certain materials like PETG.

Is 40% humidity too high for filament storage?

No, 40% RH is acceptable for short-term storage of filaments like PLA and PETG. For long-term storage (>6 months), maintaining lower humidity levels (<30%) using silica gel or vacuum-sealed containers is recommended.

Is 70% humidity too high for 3D printing?

Yes, 70% RH is far too high for 3D printing. At this level, filaments rapidly absorb moisture, leading to defects such as stringing, popping sounds during extrusion, and poor layer adhesion. Use dehumidifiers or sealed containers to mitigate these issues.